Zangge Mining places a high priority on standardized safety production management, committed to establishing a comprehensive and sound safety management system. The company actively conducts safety awareness training and promotional activities, continuously improving the safety management capabilities of all employees and contractors, and fostering a strong corporate safety culture.

Safety System Construction

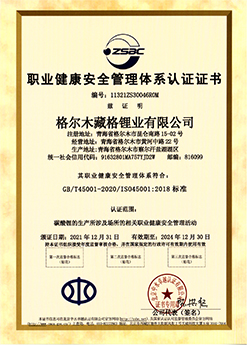

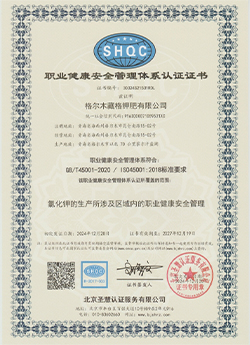

Zangge Mining strictly adheres to the Work Safety Law of the People’s Republic of China and other domestic regulations, as well as the International Organization for Standardization (ISO) Occupational Health and Safety Management System standards. The company formulates and implements policies such as the Safety Production Management System. These policies apply to all domestic production sites, employees, and contract workers, covering key topics such as safety responsibility assessment and occupational disease prevention, providing guidance for production site management. In 2024, the ISO45001 Occupational Health and Safety Management System certification coverage of Zangge Mining’s production bases, including Zangge Potash and Zangge Lithium, reached 100%. Internal and external audits are conducted annually to ensure certification validity.

Reporting Hotline:+86-028-89992276

Reporting Hotline:+86-028-89992276 Reporting Email:jc@email.zanggekuangye.com

Reporting Email:jc@email.zanggekuangye.com Mailing Address:Audit and Supervision Office, CAG Mining Co., Ltd., 19th Floor, Building 2, No. 1199 North Section of Tianfu Avenue, Chengdu High-tech Zone, China (Sichuan) Pilot Free Trade Zone, 610041

Mailing Address:Audit and Supervision Office, CAG Mining Co., Ltd., 19th Floor, Building 2, No. 1199 North Section of Tianfu Avenue, Chengdu High-tech Zone, China (Sichuan) Pilot Free Trade Zone, 610041