Sustainability

Zangge Mining embraces an open and collaborative innovation philosophy, sharing advanced technologies, participating in the development and revision of industry standards, and strengthening industry-academia-research collaborations. The company maintains close exchanges with upstream and downstream partners, industry associations, and academic institutions to promote high-quality industry development.

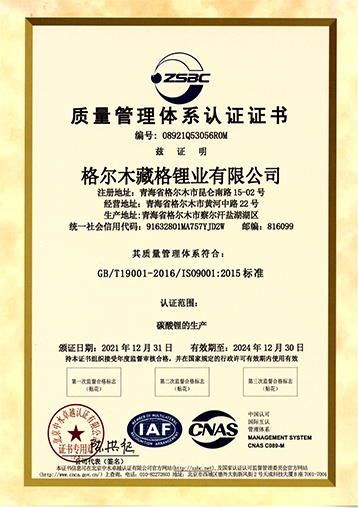

In 2024, Zangge Lithium participated in the formulation of the national standard “Brine Lithium Carbonate (GB/T 23853-2022)”, contributing to the improvement of technical and product quality standards in the salt-lake lithium extraction industry.

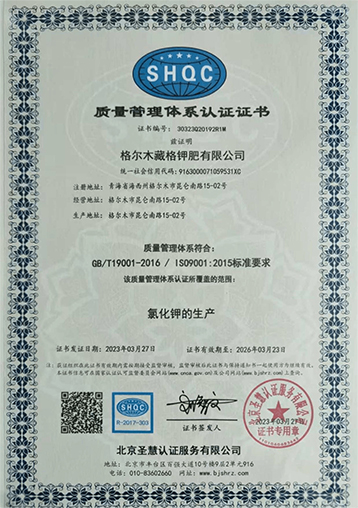

Zangge Mining emphasizes independent innovation and continuously improves R&D management and processes. Innovation is integrated throughout product development, process optimization, and digital management, driving iterative upgrades of key products such as potassium chloride and battery-grade lithium carbonate.

The company has established a structured R&D management system: President → Chief Engineer → Dedicated R&D Department, with the president steering strategy and technical experts conducting in-depth research. Regular R&D progress reporting ensures that management stays informed of technological developments, allowing strategic alignment and timely decision-making.

Official Account

Investor Relations Account

Recruitment Account

Reporting Hotline:+86-028-89992276

Reporting Hotline:+86-028-89992276

Reporting Email:jc@email.zanggekuangye.com

Reporting Email:jc@email.zanggekuangye.com

Mailing Address:Audit and Supervision Office, CAG Mining Co., Ltd., 19th Floor, Building 2, No. 1199 North Section of Tianfu Avenue, Chengdu High-tech Zone, China (Sichuan) Pilot Free Trade Zone, 610041

Mailing Address:Audit and Supervision Office, CAG Mining Co., Ltd., 19th Floor, Building 2, No. 1199 North Section of Tianfu Avenue, Chengdu High-tech Zone, China (Sichuan) Pilot Free Trade Zone, 610041

Scan with WeChat