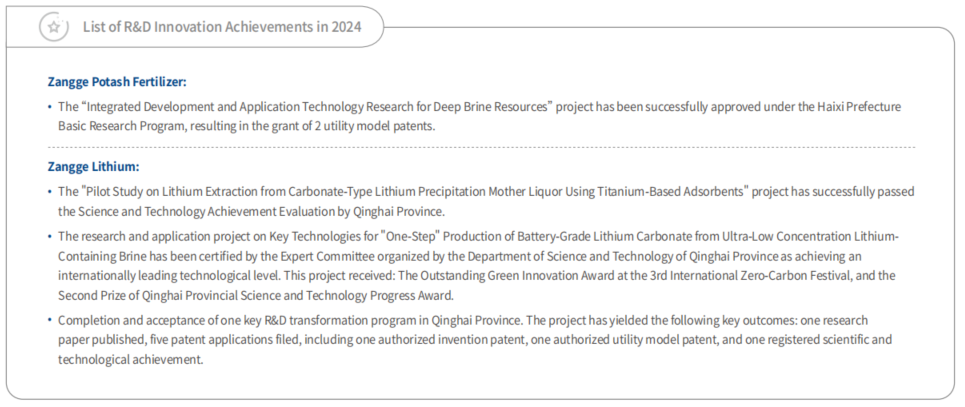

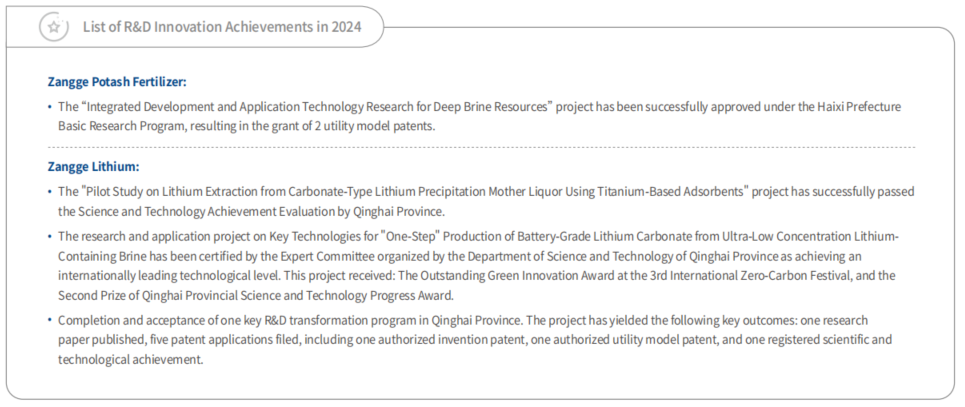

Zangge Mining places a high priority on building independent innovation capabilities and continually refining R&D management and processes. The Company drives innovation across the entire value chain—from product development and process optimization to digital management—accelerating iterative upgrades in core products, such as potassium chloride and battery-grade lithium carbonate, along with related technologies. The Company stimulates innovation vitality through standardized R&D management procedures while leveraging its strengths to collaborate with both upstream and downstream partners, promoting integrated development across the industrial chain.

In terms of innovation governance, Zangge Mining has established a three-tier R&D management structure comprising the President, Chief Engineer, and a Dedicated R&D Department. The President directs the strategic vision of the Company while laboratory professionals conduct in-depth research to empower innovation. Regular progress reporting on R&D initiatives enables management to maintain realtime oversight of cutting-edge technological developments and facilitate data-driven decision-making that aligns with strategic objectives.

Industry Development

The Company adheres to an open and win-win cooperation philosophy, actively engaging in several initiatives to promote industry advancement. We focus on sharing our cutting-edge technological achievements and participating in the formulation and revision of industry standards. By strengthening collaborations between industry, academia, and research institutions, we have established close partnerships with upstream and downstream enterprises as well as industry associations. Through these collaborative efforts, we effectively contribute to the high-quality development of the industry.

In 2024, Zangge Lithium actively participated in developing the national standard for Lithium Carbonate Made of Brine (GB/T 23853-2022), contributing suggestions to enhance technical standards within the salt lake lithium extraction industry.

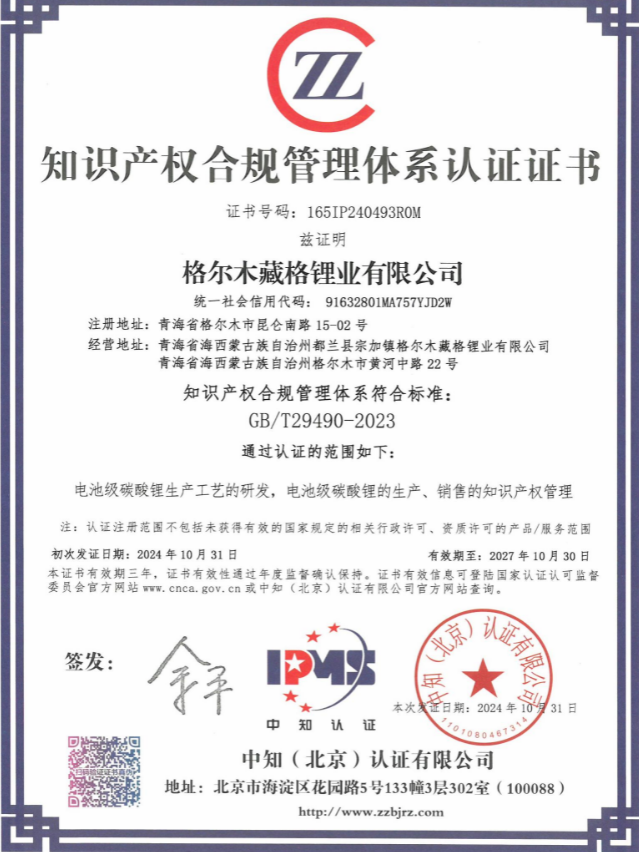

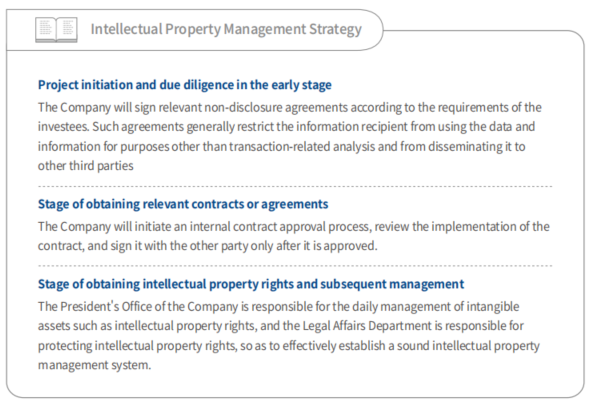

Intellectual Property Protection

In 2024, Zangge Lithium undertook a comprehensive optimization of its intellectual property management system, which involved the completion of system documentation for its compliance management system, and successfully achieved certification under the updated national standard Enterprise Intellectual Property Compliance Management System—Requirements (GB/T29490-2023). Consequently, Zangge Lithium was awarded the "Certificate of Intellectual Property Compliance Management System Certification". Furthermore, Zangge Lithium adheres to the principle that "technological innovation drives core competitiveness, while standardized management leads corporate development". In line with this philosophy, the Company has established 3 to 5-year objectives for intellectual property management along with long-term goals, which serves as a benchmark for enhancing the company-wide intellectual property management system.