Climate change ranks among the major challenges of our time and is one of the most pressing non-traditional security issues confronting contemporary society. To address climate change and mitigate its impacts on society, Zangge Mining strictly fulfills its environmental protection obligations throughout production and operations, aligns with the growing trend of green operations, and consistently fosters positive synergies between ecological protection and business growth. Meanwhile, the Company actively implements climate change mitigation policies, promotes green and low-carbon development, and contributes to achieving the national goals of carbon peaking and carbon neutrality.

Identification and management of climate risks and opportunities

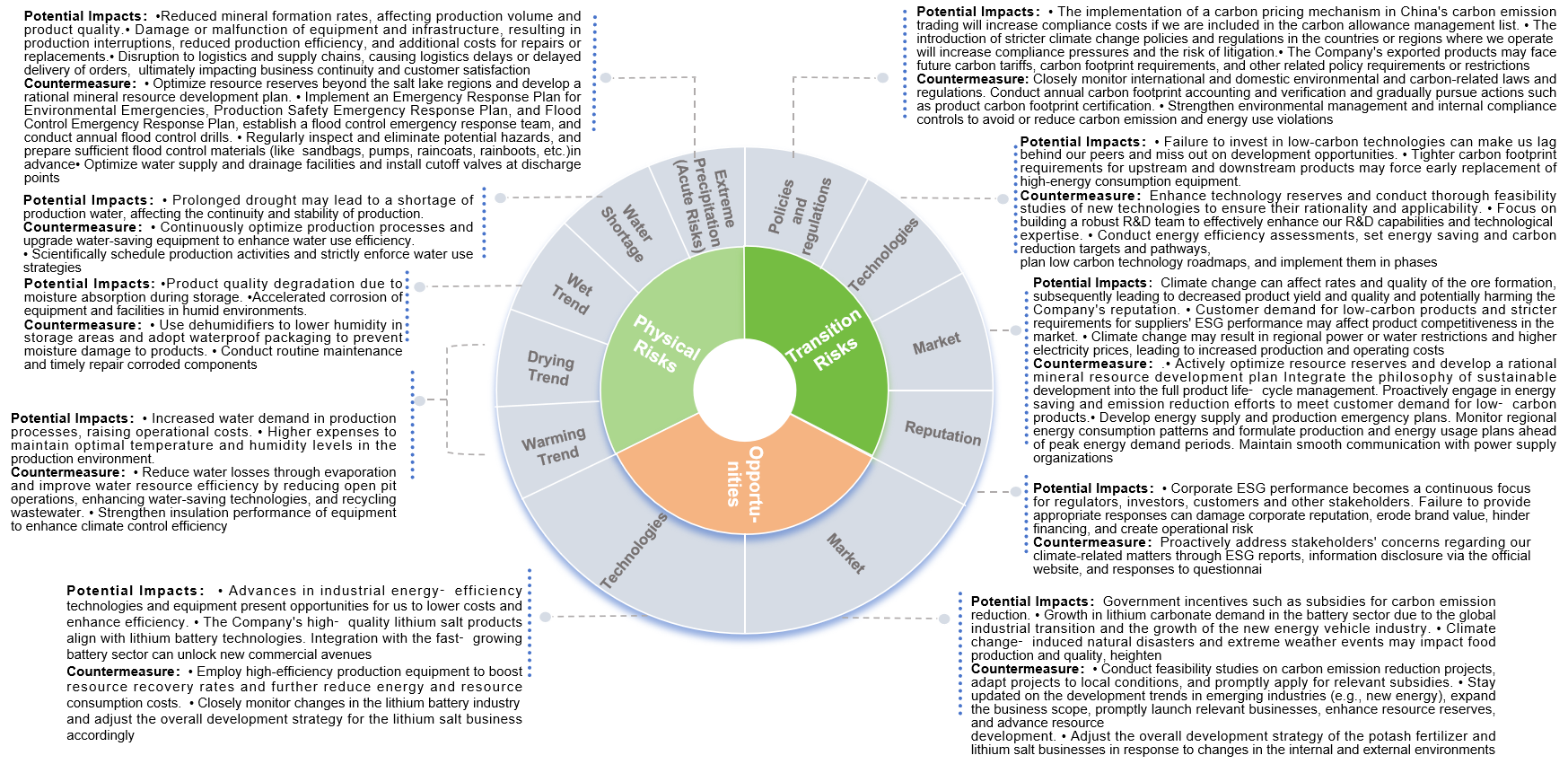

We have performed a scenario analysis using two Representative Concentration Pathways (RCPs) adopted by the Intergovernmental Panel on Climate Change (IPCC)—namely RCP4.5 (low-carbon emissions scenario) and RCP8.5 (high-carbon emissions scenario). Through this analysis, we have comprehensively identified our potential physical risks in the short term (by 2030), medium term (by 2050), and long term(by 2080). The results are presented below:

Transition Risks and Opportunities

Against the backdrop of the global green industrial transformation and China's national "Dual Carbon" strategy, climate-related policies and regulations, technological innovations, market sentiment, and shifting consumer preferences pose potential compliance risks and cost pressures for enterprises. In response, Zangge Mining has identified and assessed transition risks based on factors including its business development, external policy changes, and industry trends and has formulated preliminary corresponding solutions. At the same time, the Company has also identified opportunities in the market and technologies arising from the low-carbon transition, formulated targeted strategic development plans, and adjusted them accordingly to ensure continuous and steady growth.

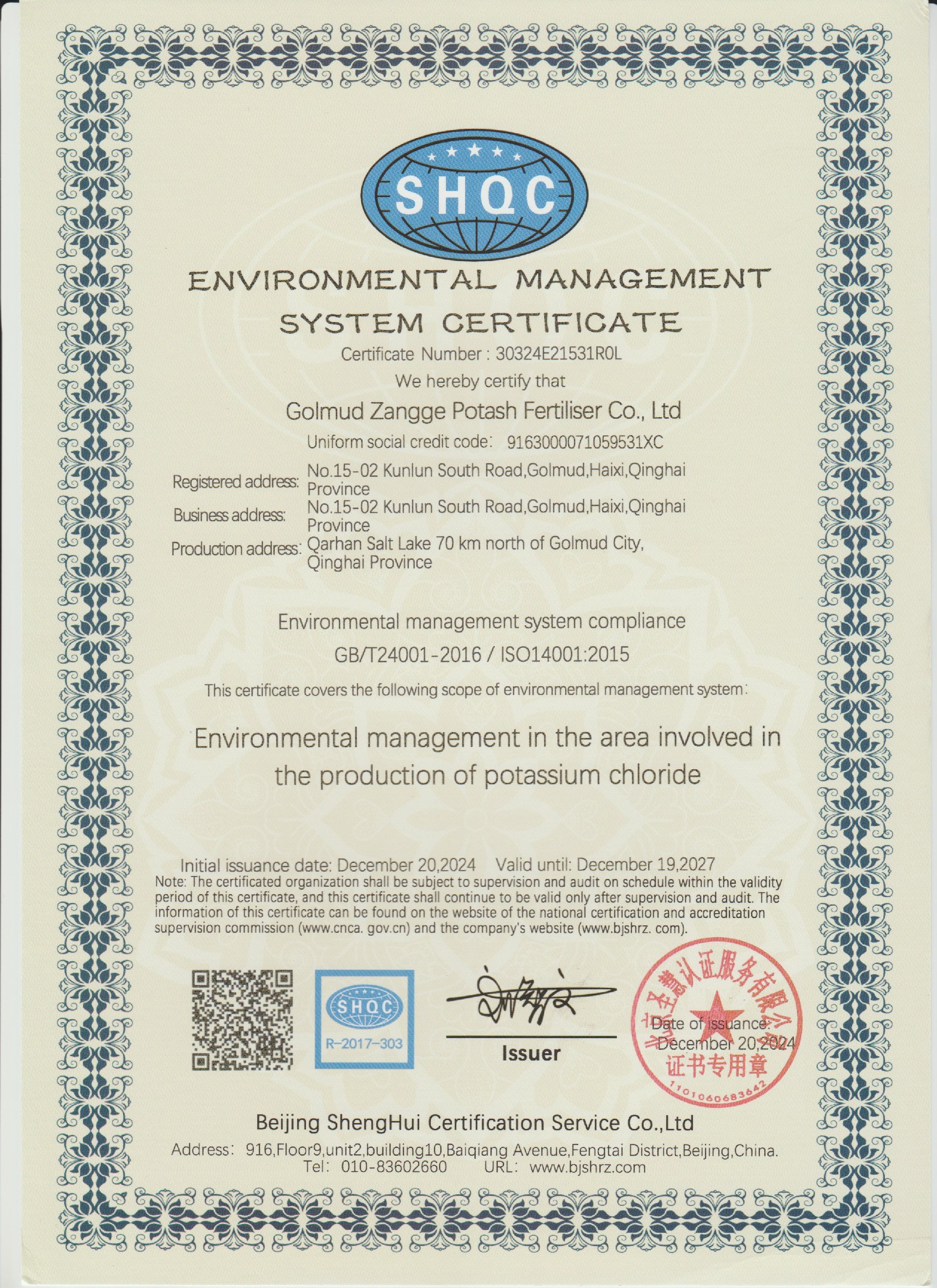

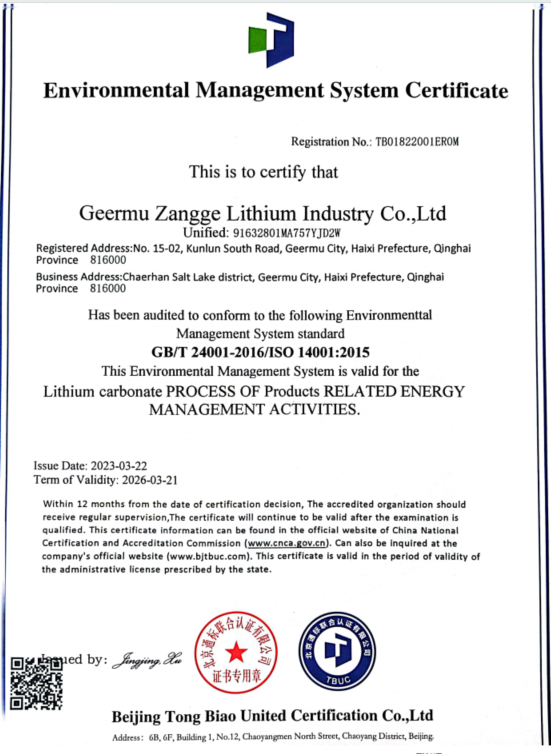

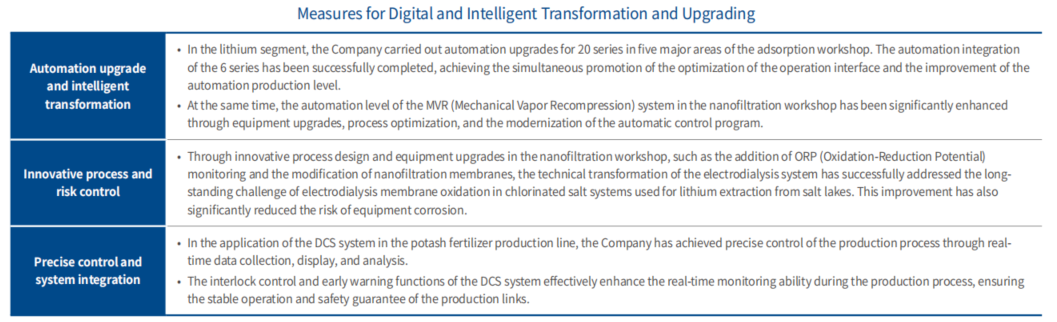

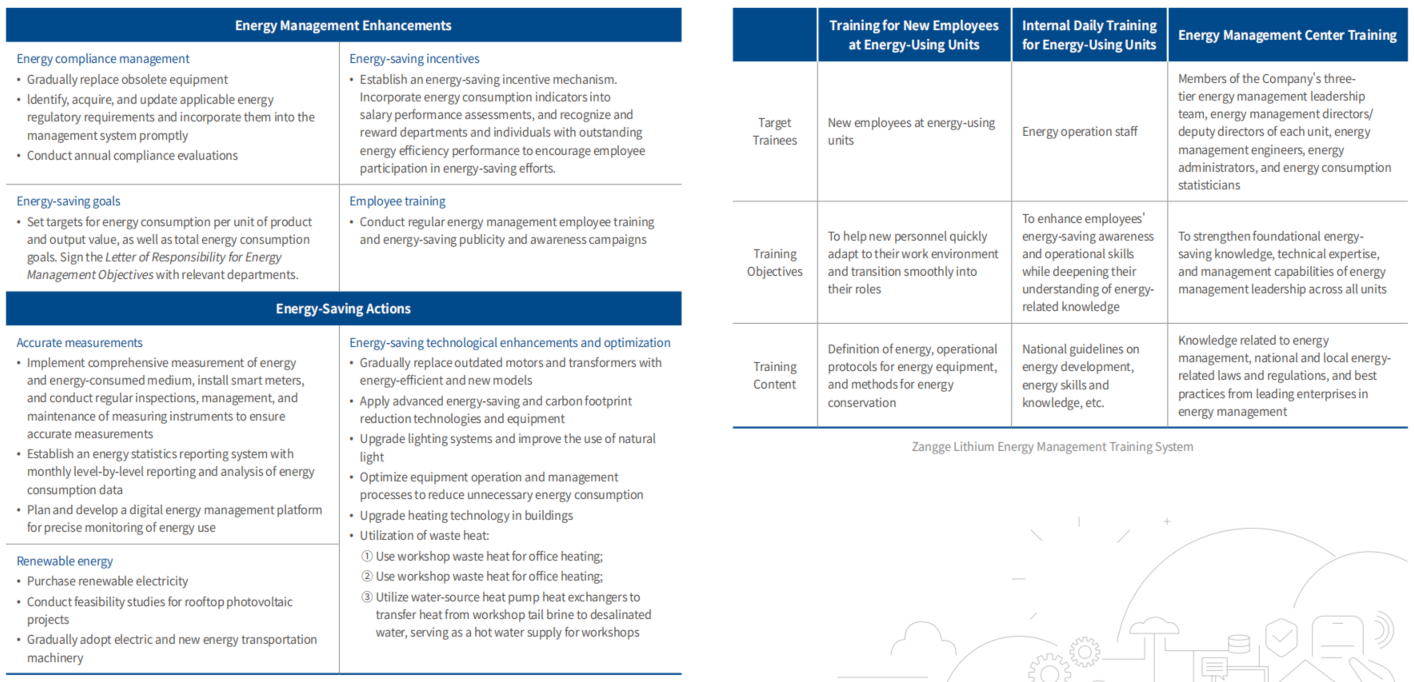

Zangge Mining strictly adheres to the Energy Conservation Law of the People's Republic of China and other relevant regulations. We have developed and actively implemented several procedural documents, such as the Energy Management Regulations, Energy Consumption Measuring Management System, Energy Saving Incentive Scheme, Energy Performance Parameter Control Procedure, and Energy Manual, and established an energy management system under ISO 50001. By the end of the reporting period, both the Company's production bases, Zangge Potash Fertilizer and Zangge Lithium, have achieved the ISO 50001 energy management system certification. To ensure compliance with the energy management system, we conduct internal audits annually and undergo third-party external audits every three years. Each year, we set energy management goals and implement a range of energy saving measures to realize these targets.To further strengthen energy governance, we have established a three-tier energy management system. This network promotes the active participation of everyone within the Company in energy management affairs. Additionally, the Company has established an energy management leading group headed by the President responsible for oversight and decision-making related to energy management.

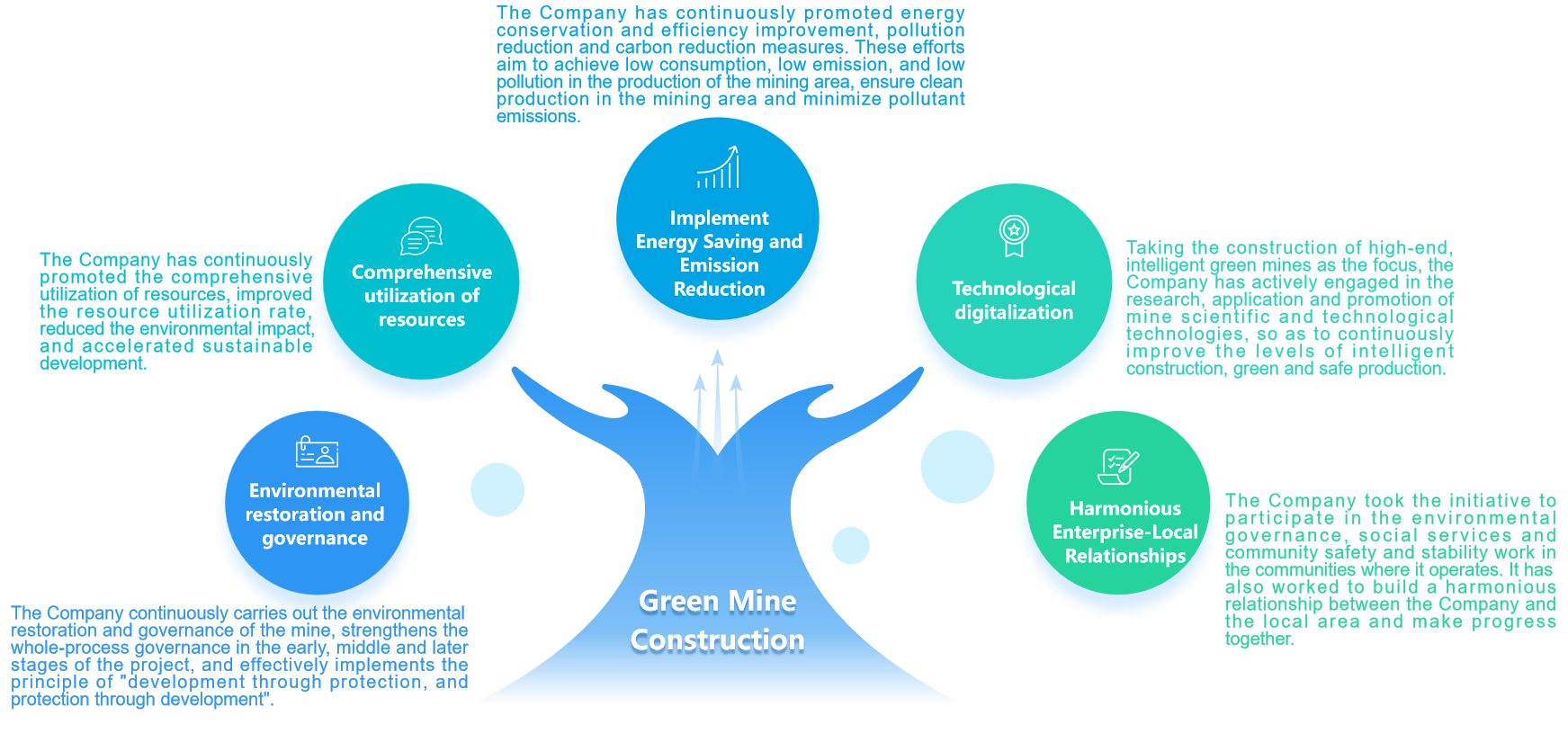

Strategy and Management Method

The Company upholds an energy policy focused on "legal compliance, continuous improvement, innovative development, cost reduction, and efficiency enhancement" and continuously refines its energy‑management capabilities. We conduct company-wide energy saving assessments to fully explore energy saving opportunities and lower energy use costs while enhancing efficiency. This year, Zangge Potash Fertilizer also completed a comprehensive energy management audit covering production workshops, mining workshops, office areas and auxiliary facilities. Drawing on assessment and audit findings, we are striving to fully elevate our energy management through measures such as strengthening compliance oversight and improving measurement accuracy, undertaking energy saving technological enhancements and optimizations, and strengthening employee training in energy conservation.

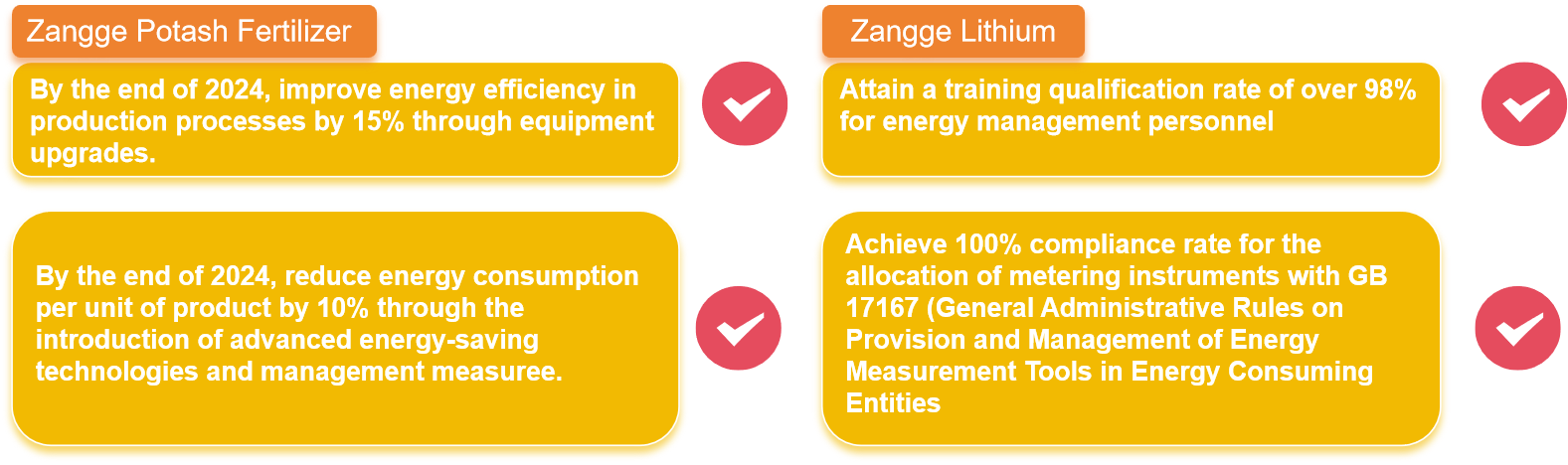

Metrics and Targets

In 2024, both Zangge Potash Fertilizer and Zangge Lithium established detailed energy management objectives. Additionally, Zangge Lithium signed the Letter of Responsibility for Energy Management Objectives with all relevant energy management personnel to promote the achievement of energy-saving and emission-reduction goals. Furthermore, Zangge Potash Fertilizer and Zangge Lithium set energy control indicators for 2024, covering metrics such as comprehensive energy consumption and electricity consumption per unit of product, thereby strengthening energy performance management. By the end of the reporting period, the progress toward energy management objectives is as follows: